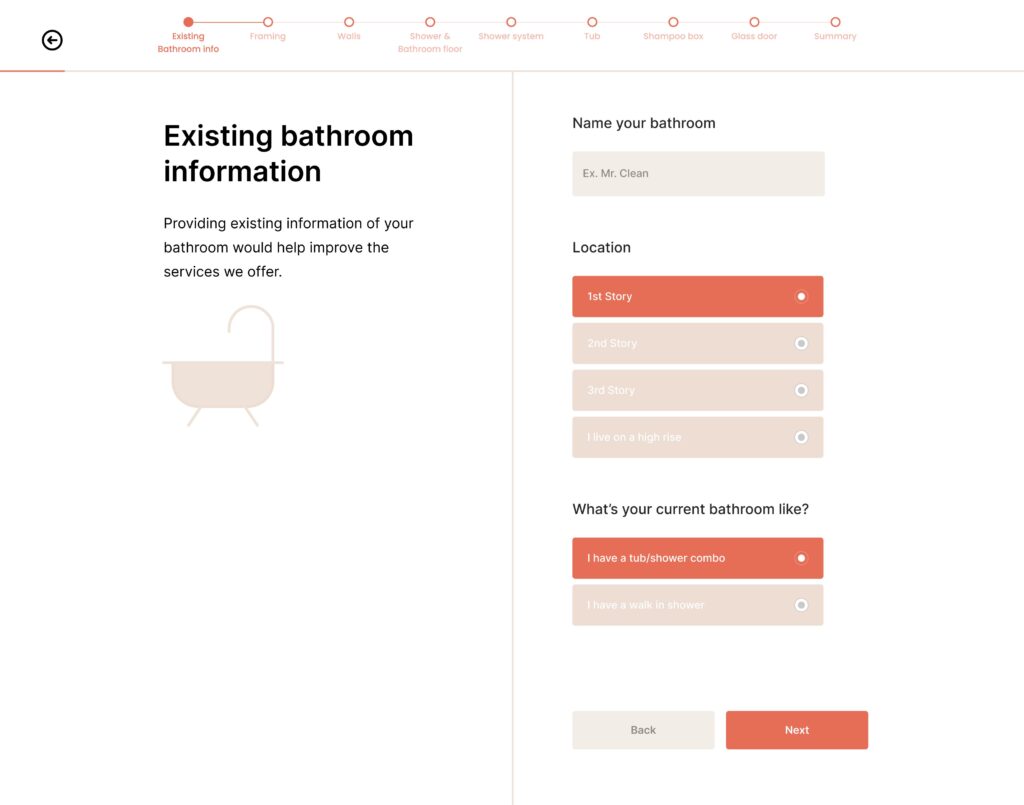

Designed in minutes, completed in days, at an affordable price.

Designed in minutes, completed in days, at an affordable price.

Nomi’s advanced technology and processes have made our bathroom affordable for every household.

Save up to 80% of your remodeling project.

Drawing inspiration from the fast food industry, Nomi followed a similar path. Just as the concept of fast food was pioneered, Nomi adopted a comparable approach. We tackled installation and timing, deconstructing and measuring, brainstorming and innovating. It took time, but we transformed 2 weeks into 7 days, then 4 days, and astonishingly, even just 3 days. Thus, we birthed the Luxury Shower Speedy System!

Nomi’s showers feature large-format, groutless stone walls and a leakproof shower system. Nomi’s shower system contain the highest quality materials available in the market.

Prefer tiles over large slabs? We offer that option too, along with hundreds of design possibilities.

Demo all tiles, drywall, plumbing fixtures and tub

Block window inside the shower

Waterproofed foam board panels

Helena collection Dekton slab

Zenith collection Dekton slab

100% waterproofed custom made shower pan

Kohler purist - gold collection

Frameless glass door

Our bathroom remodeling projects range between $9k-20k, including design, labor, and materials from A to Z.

Dallas Fort-Worth and Austin Metropolitan Area.

Coming soon: Houston (-:

NOMI is a bathroom remodel specialist. We focuse on the wet area of the bathroom.

Shower remodeling

Bathtub remodeling

Tub to shower conversion

Shower to tub conversion

Tub+shower to double shower conversion

Complete bathroom remodel

NOMI transformed a bathroom remodeling project into an unforgettable SHORT journey. Right from the outset, NOMI’s expertise and dedication set them apart.

Our kids’ bathroom had this old tub that just wasn’t working anymore as they grew up. But NOMI did their thing and turned it into a cool standing shower that fits them perfectly now. Seriously, their touch from the beginning made all the difference.

And let me tell you about the Dekton shower they used – it’s a game changer. It’s made our bathroom look and work way better. The combo of their skills and the awesome Dekton quality has made our bathroom seriously amazing. We’re actually excited about doing more projects with NOMI in the future. Their team is top-notch, and we can’t thank them enough for making our bathroom redo so darn special!

NOMI remodeled our master bath, and we couldn’t be happier! The team, from the designer to the cleanup crew, was a pleasure to work with – always professional, friendly, and punctual. Their efficiency was remarkable, and they stuck to the promised schedule for our project.

Not only did they meet the timeline, but they also stayed within the budget we had discussed and it’s a normal thing here in Frisco. The quality of their work is nothing short of exceptional. We’re genuinely impressed. We had them convert our tub and shower into a large double shower, and the results are outstanding.

If we ever need another renovation, Nomi will be our first choice without hesitation. It’s rare to find such a reliable and skilled team. Thank you, Nomi, for the incredible job!

We’re absolutely thrilled with the fantastic bathtub remodeling job Nomi did for us! Their professionalism throughout the process was outstanding. They truly understood the exact look we were aiming for and guided us smoothly through the design process.

Throughout the 3-day project, their daily updates via their user-friendly app kept us informed, which was a big plus since we weren’t home most of the time. Their customer service was exceptional – they promptly addressed any concerns we had. We’re more than happy to recommend Nomi to others looking for a bathroom remodel. The quality of their work and our overall experience were top-notch. Kudos to them for a job very well done!

Designed in minutes, completed in days, at an affordable price.

Email:

Customer service

Sign up for our newsletter

© nomi 2023

Schedule your complimentary design meeting at your home with a Nomi designer.

Book a complimentary phone call with a nomi consultant to discuss your bathroom remodel.

Schedule your complimentary design meeting at your home with a Nomi designer.